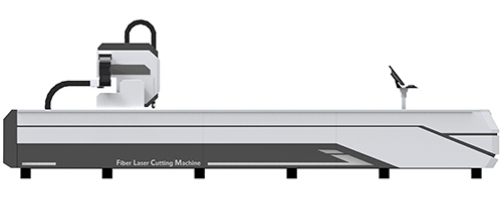

Single bed flat metal cutting fiber laser cutting machine

Applications:

Fiber laser metal cutting machine is widely used in various industries, such as aerospace and automotive industry, advertising industry, decoration industry, kitchen and kitchen ware, engineering machinery, steel and iron, automobile, metal plate chassis, air-conditioner manufacturing, metal plate cutting, metal craft, building model, etc.

Features

Fiber sheet metal laser cutting machine adopts most sophisticated fiber laser, combining self-design Gantry CNC machine and high strength welding body. After high temperature annealing and precision machining by large CNC milling machine, it has good rigidity and stability with imported high precision and fast speed, linear guide drive. Aluminum beam, advanced heat treatment process, high strength, light weight, good rigidity. It is mainly for cutting sheet metal below in high speed and high precision.

Fiber laser has a series of advantages, such as high beam quality, high brightness, high conversion rates, stable and reliable operation of low cost. Low Energy Consumption, save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 machine. The laser source lifetime is more than 100,000 hours and almost free maintenance for life.

Parameters:

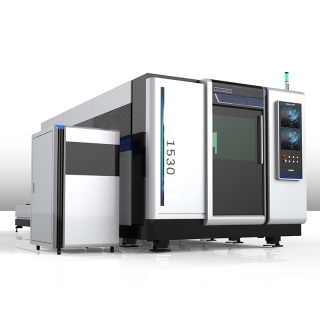

Model | JY1325V JY1530V JY2040V JY2060V |

Working area(mm) | 1300X2500 1500X3000mm 2000X4000mm 2000X6000mm |

Laser power(W) | 300-4000W |

Laser wavelength | 1070nm±10nm |

Max moving speed | 120m/min |

Max cutting speed | 30m/min |

Max acc. speed | 1.5G |

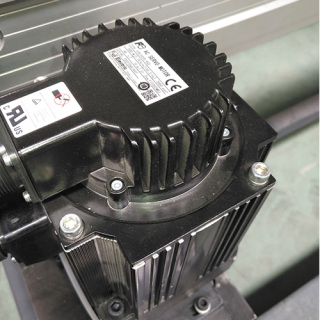

Transmission | Double drive design, high precision rack gear and rail |

Driving system | Servo motor |

X Y positioning accuracy | ±0.02mm |

X/Y repeat positioning accuracy | ±0.02mm |

Working voltage | 380V/50HZ |

Plate positioning | Automatic edge search positioning |