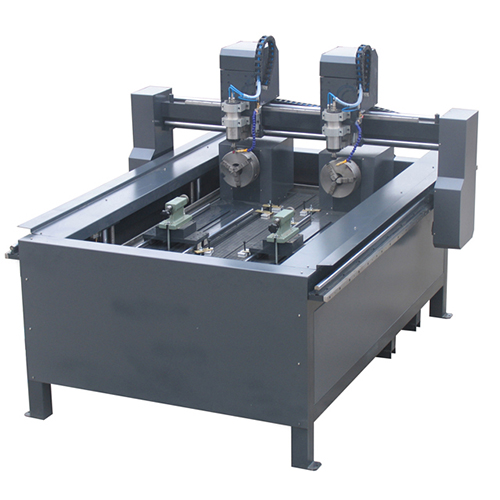

Rotary and flat engraving CNC router

Applications:

Applied to complex three-dimensional craft work piece such as furniture, sofa legs, stair columns, and Buddha crafts etc

Features

1. Welded structure of thick profiled steel and inner stress removed by vibration ageing treatment, strong lathe bed makes the machine with rigidity, no distortion

2. Y axis driven by double motors, high accuracy rack gears transmission, powerful and stable movement. Up-down working table with 2 KW 3 phase asynchronous motor; gearbox with worm and worm wheel transmission drives chain wheel with large pitch and 4 ball screw; working table rises and falls on 4 guiding cylinders firmly and smoothly. The maximum lifting weight is up to 1500 KGS.

3. Rotary attachment with chuck and dead tail moving on linear square rail with high precision concentricity. The chassis is made with L -102 integrally cast technology. The maximum work piece diameter 400mm, and the length up to 1200mm, weight of 56KGS and collocated with balance trolley.

4. Options: stainless steel tank for processing stones and configured with auto water supplying device as well.

5. Rotary attachments model 4021 can be fixed to the working platform. The machine can work on thick material (max. 700mm). The attachments can be removed from the machine when column work piece is not processed. Then the machine becomes a normal router.

Parameters:

Lathe bed | Welding |

Spindle | 2.2KW*2 |

Control system | DSP or NC studio |

Rotary diameters | 4-200mm |

Rotary accuracy | ≤0.05m |

Resolution | 0.05mm |

Command language | G CODE, HPGL |

Software | ARTCAM, TYPE3, UCANCAM |

Working voltage | AC220V 50HZ/60HZ |