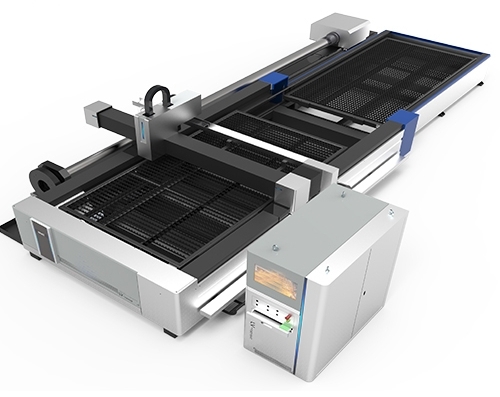

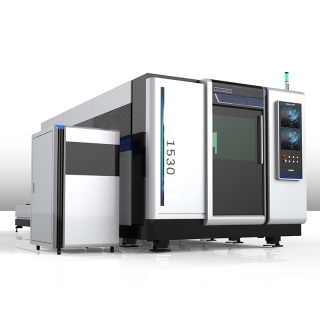

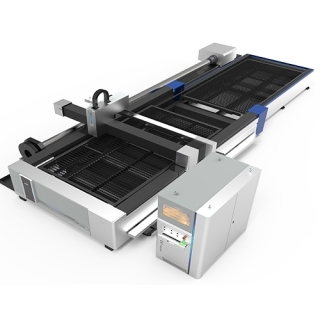

Plate and tube integrated laser cutting machine

We specialize in cutting square pipe, round pipe, rectangular pipe, elliptic pipe, D pipe and hexagon pipe

The plate is specially used for cutting 0.5-25mm carbon steel plate, 0.5-16mm stainless steel plate, cold-rolled plate, electrolytic plate, 0.5-16mm aluminum alloy plate,

0.5-10mm brass and red copper and other metal materials.

Petroleum pipe, fitness equipment and other pipe based mechanical processing, automobile manufacturing,

chassis, cabinets and other plate based mechanical processing

Laser sheet and tube fiber laser cutting machine is a high-performance cutting machine specially designed for comprehensive metal manufacturing.

1. The board and tube are dual-purpose to meet the needs of two kinds of processing. Save more than 50% of space and improve production efficiency.

2. The laser electro-optical conversion rate is high, up to 30% or more, which can significantly save power consumption and reduce production costs.

3. Customize as required. The cutting board part can adjust the size of the worktable and the single and double platforms according to customer needs.

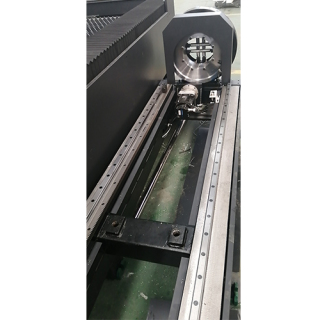

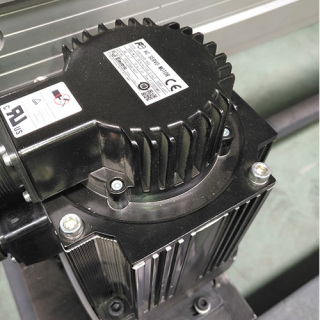

4. This machine adopts pneumatic full-stroke chuck, the maximum clamping range can reach 15-220mm round pipe, high-precision chuck with high-precision servo deceleration system, the cutting effect is excellent.

Plate Welding Heavy Work Bed

High impact resistan Laser sheet and tube fiber laser cutting machine is a high-performance cutting machine specially designed for comprehensive metal manufacturing.

Professional Sheet & Tube Cutting System

Cypcut Laser Cutting System

More user-friendly human-machine interaction;

Simple, economical, practical and convenient;

Highly integrated and highly intelligent with file reading, design, output and processing control all in one.

Professional Sheet & Tube Cutting System

It adopts an pneumatic clamp design on both sides and it can modulate the center automatically.

The diagonal adjustable range is 20-220mm.

Technical Parameters

| Machine model | 3015CNR |

| Laser power | 1000W 2000W 3000W 4000W 6000W 8000W(Optional) |

| Dimensions | 4600*2450*1700mm |

| Working area | 3000mm x 1500mm |

| Repeat positioning accuracy | ±0.02mm |

| Maximum speed | 120m/min |

| Maximum acceleration | 1.5G |

| Specified voltage and frequency | 380V/50Hz/60Hz/60A |