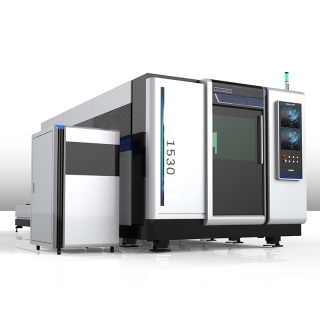

Flame and plasma cutting machine

Industrial plasma cutter applications:

Parts cutting, thickness material and heterotroph sheet cutting

Industrial plasma cutter

The bed includes beams and columns. The whole machine requires good rigidity, high strength, high processing accuracy, reliability and stability. The bilateral drive ensures the synchronization of the two ends of the beam, and the two ends of the main column are equipped with horizontal elastic guides In order to ensure the stability of the machine during operation, the walking is stable and reliable;

The beam adopts German technology box beam structure

Features:

1. Industrail plasma cutter's gantry structure is large and adopts low center of gravity

2. Bilateral drive adopts symmetrical structure of industry plasma cutter.

3.Industrial plasma cutter single drive adopts equicrural structure.

4. Industry plasma cutter adopting high precision planetary gear reducer made by EISELE

5. Industry plasma cutter cutting torch driven up and down by bearing

6. Industry plasma cutter is adopting 8KgU71Mn high strength guide rail for Y axis and solenoid valve imported from Italy.

Parameters:

Track gauge | 3000-7000mm |

Track length | 6000-12000mm |

Cutting width(mm) | 2200-6200mm |

Cutting length(mm) | 4000-10000mm |

Control system | SHANGHAI FLMC-F2300/BEIJING STARFIRE |

Cutting torch | 2 sets |

Cutting thickness | Flame 6-200mm,Plasma cutting decided by plasma power |

Travelling speed | 8000mm/min |

Cutting thickness | Depend on the thickness of the board |

Driving mode | Bilateral drive |