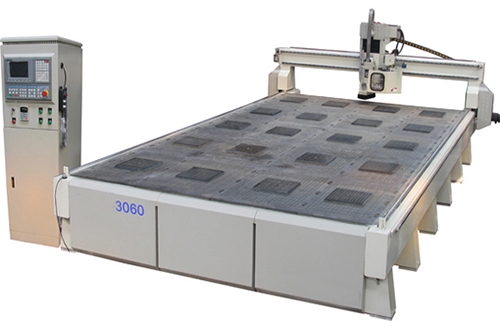

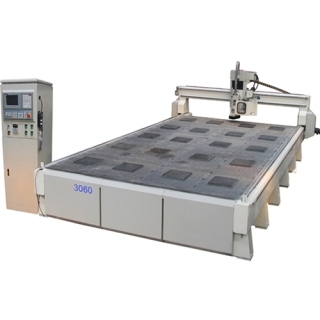

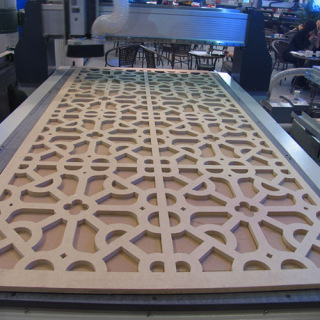

3060 woodworking cnc router

Applications:

The main use is villa door for engraving, for the production of cabinet doors, solid wood doors, computer tables, furniture etc. It can be used for large-area, flat carving large production MDF, solid wood panels, cutting, 3D relief and other production process.

Features:

1. Fuselage with thick welded steel pipe, high temperature tempering treatment to ensure the body deformation, rigidity and strength.

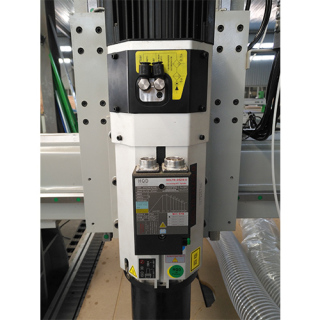

2. Key institutions in this paragraph models are made of precision parts assembled. Coupled with high torque servo motors in Japan, so the machine has stable operation, low noise, high speed, high precision positioning.

3. Using imported Italian air-cooled tool change spindle, high precision, long life, smooth operation, long working stable and reliable. The imported magazine, free to quickly exchange the required tool, dedicated to knife sets, tool length compensation can be exact error.

4. Tops, dual-chamber adsorption, the choice of high strength sheet once milling is made with high adhesive force.

5. Imported operating system, split keyboard control, color LCD screen, more powerful.

6. Powerful vacuum system to ensure no dust flying phenomenon in the process.

7. Automatic lubrication system with just one touch, easy to complete regular maintenance.

Parameters:

Description | JY3060 |

Working Area (X * Y * Z) | 3000*6000*450mm |

X Y Z Positioning Accuracy | ≤0.05mm |

X Y Z Reposition Accuracy | ≤0.05mm |

Table Surface | Vaccum table(Bakelite) |

X,Y transmission | Square rail and rack gear |

Z axis transmission | Ball screw |

Max power Consumption(without spindle) | 28KW |

Max travel speed | 80m/min |

Max Engraving Speed | 20m/min |

Spindle Power | 8.0KW |

Driver system | |

Tool Diameter | φ3.175- φ20 |

Software | TYPE3/UCANCAM |